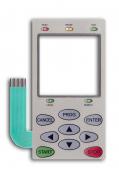

Flexible membrane keyboards

Keyboards are made on flexible printed circuit boards based on 0.125-0,150 mm polyester film. The conductors on flexible substrates are made using two main methods:

1) the method of screen printing using silver-filled or graphite-filled conductive pastes or their combinations as the conductive material. Circuit resistance is up to 300 ohms.

2) the method of etching the PCB conductors on foiled polyester or polyimide film, followed by local nickel plating of the contact zones in the membrane mounting spots. Tactile feedback on the membrane keyboards is achieved by shaping the front shield film or by embedding of metallic switching membranes.

Membrane keyboard specifications

|

Pressure force, g |

60… 600 |

Membrane keyboard thickness, mm |

<1,2 |

|

Keystroke, mm |

0,15… 0,4 |

Switching current, mA |

0,05 …100 |

|

Average useful life, years |

3 |

Switching voltage, V |

0,5 … 40 |

|

Warranty life, key depressions |

1 х 10 6 |

Contact resistance at 100mA current, Ohm |

|

The main attractive factor of control panels based on conductive pastes is a low cost with a relatively big lots (1000 pcs and more). But they have much higher circuit resistance compared with control panels on foiled films - up to 300 ohms per conductor. Such keyboards are manufactured mainly without the use of embedded metal membranes – in this case the second flexible PCB acts as a contactor. The tactile feedback is either absent ('feather-touch') or is achieved by shaping the front film. When installing metal membranes, a significant improvement in tactility can be achieved, but the useful life reduces due to mechanical destruction of conductive paste contact zones by the membrane. It is possible to install signaling LEDs on keyboards based on conductive paste – the LEDs are bonded to the front-side of the PCB using the conductive adhesives, meaning that the LCD is placed under the shield on the front side and is fully sealed. An output FFC is an extension of the flexible PCB, i.e. no soldering or mechanical fastening, thus increasing reliability. Keyboards may be supplied with clincher-type connectors.

Control panels on the basis of foiled films have all advantages of keyboards on foiled glass-fiber laminate: a wide range of operating temperatures and low resistance of copper connector strips (compared with keyboards on conductive pastes), here the output FFC is an extension of the flexible PCB, i.e. no soldering or mechanical fastening, thus increasing reliability. As a rule, at the end of the FFC a punch-type connector is installed, which has the fixing tabs punching through the film around the FFC copper conductors and securely fixing the connector, ensuring high resistance to vibration and impacts. Another advantage is the possibility of soldering the signal SMD LEDs on the side of the membrane installation on the flexible PCB. The maximum thickness of panels to be installed in a plastic casing - 0.9 mm, in a metal casing - 1.2 mm.

The only disadvantage of such control panels is that they are relatively expensive compared with the control panels based on glass-fiber laminate boards due to higher prices of foiled films and the need to fabricate the punch tooling. Keyboards based on polyimide PCB have copper conductors and nickel-plated of contact areas and commutator segments, and we can do the galvanic gilding. The galvanic gilding makes it possible to extend the service life up to 15 years.